Integrating with Scanning Systems

Many materials processing systems would ideally be addressed with scanning systems. The general architecture of a scanning system calls for the laser beam to be steered at different angles to cover a given area. Just tilting the beam, however, leads to asymmetries and variations in power density across the field. Those effects can be minimized by using an F-theta lens — a lens fabricated to compensate for distortions across a given field. The laser beam on the input side of the lens is tilted, and on the output side it is displaced across a flat field specific to the design of the F-theta lens.

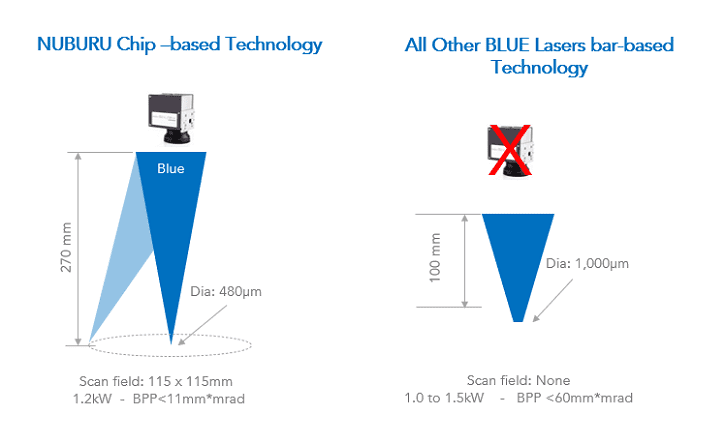

F-theta lenses, however, inherently enlarge the spot size at the focus. Low divergence — that is, high brightness — becomes a critical performance parameter. Consider the industry standard field of 115 X 115 mm at a working distance of 270 mm. To address this with a 480-µm spot the Beam Parameter Product needs to be better than 12, that is, less than 12.

Why a 480-µm spot? Because a 1.2 kW laser in a 480-µm spot delivers a power density under the threshold for introducing spatter and voids.

Integrated with such a scanning system, the NUBURU AI-series enables the highest possible processing speed for defect-free copper welding.