High-Brightness by Design

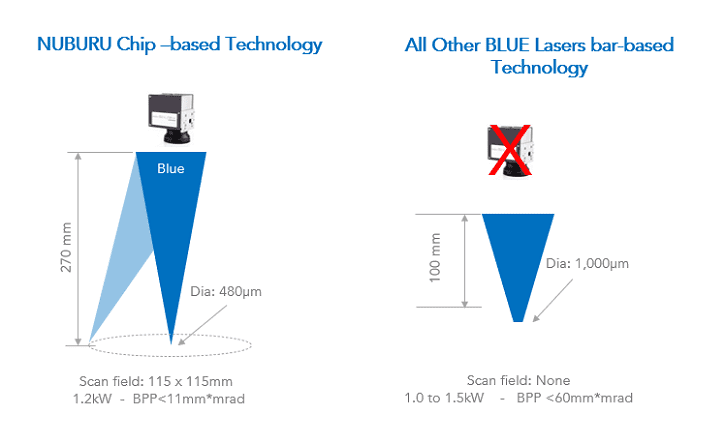

Brightness is a measurement of light power “concentration.” Beam parameter product (BPP) is a laser specification indicating the beam “spread.” For a given output power, the brightness is maximum when the BPP is smallest.

The trick, then, is to design a system that has both high power and a small BPP. High power blue lasers combine outputs of many individual diodes. It takes some clever engineering to do this without making the BPP larger. That’s important, because once the BPP gets larger, it can’t be made smaller.

To optimize beam quality, the output of each of the many diodes needs to be circularized and collimated. NUBURU does this with individual actively aligned micro-optics for each diode. The individual beamlets are then spatially brought together. That preserves the BPP while creating a high-power beam.

As an alternative, consider diodes in a linear array — a bar. Even if circularized, the beams are spread out. When collimated and combined with a single lens, the angular divergence gets very large. The BPP is then dominated by the angular spread. And, once lost, the BPP can’t be recovered. Larger BPP means smaller brightness, and that leads to lower power density and consequently longer processing times.

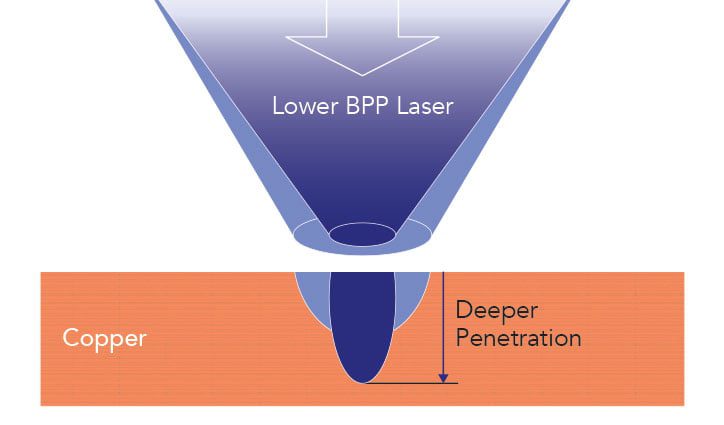

NUBURU’s approach maintains a small BPP, and that means higher brightness and higher power density. For welding that means faster processing speed, deeper weld penetration, or both.

You may not need to know the design details, but you need the end result: higher power density and improved performance.